Denitrification – Effective Reduction of Nitrogen Oxides (NOₓ) from Flue Gases

Denitrification is the process of removing nitrogen oxides (NOₓ) from flue gases generated during the combustion of fossil fuels, biomass, and various industrial processes. NOₓ are significant pollutants that contribute to the formation of smog, acid rain, and have harmful effects on human health and the environment.

Denitrification Technologies We Offer

- Selective Non-Catalytic Reduction (SNCR) – injecting ammonia or urea into the boiler at temperatures of 900–1,050 °C. The reduction efficiency of NOₓ is 40–60%. This technology is easier to install but less effective than the catalytic version. Urea is often used as a safer alternative to ammonia.

- Selective Catalytic Reduction (SCR) – injecting ammonia into flue gases before entering the catalytic reactor. The reaction occurs at temperatures of 300–400 °C, with efficiency reaching 80–90%. Catalysts are made from vanadium, molybdenum, or tungsten oxides.

Denitrification

SCR technology for NOₓ reduction in flue gases. The reduction of NOₓ to the desired level is achieved using a catalyst and a reagent, which in this case is a 40% aqueous solution of urea.

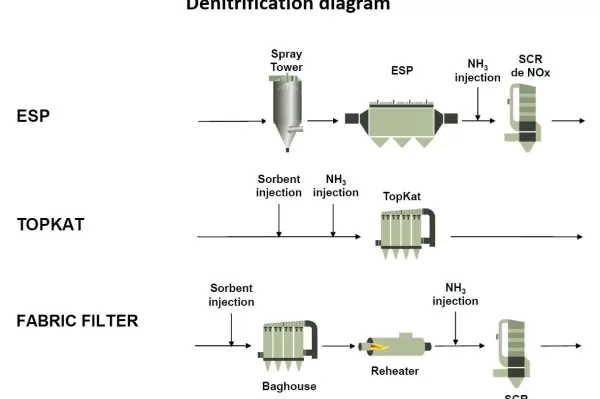

Flue Gas Denitrification Diagram Using Different Technologies

- The top section shows the process with an Electrostatic Precipitator (ESP), ammonia injection, and the subsequent SCR reactor for NOₓ reduction.

- The middle section illustrates the variant with the TopKat filter, where sorbent and ammonia are injected before the filter.

- The bottom section depicts the use of a fabric filter (baghouse), a reheater, and ammonia injection before the SCR reactor for NOₓ emission reduction.

Why Choose DEPURO Denitrification Technology?

- High NOₓ emission reduction efficiency – up to 90% depending on the selected method.

- Proven technologies – Selective Non-Catalytic Reduction (SNCR) and Selective Catalytic Reduction (SCR).

- Choice of ammonia or urea based on operational and safety requirements.

- Customized solutions – design based on temperature and operational conditions.

- Turnkey solutions – from design to installation and operational optimization.

Request a Denitrification Technology

Do you want to reduce nitrogen oxide emissions and meet regulatory limits? Contact us – we’ll design a denitrification technology tailored to your operational conditions.