Desulfurization – Effective Reduction of Sulfur Oxides (SO₂) from Flue Gases

Desulfurization (DeSOₓ) is a process that removes sulfur oxides, primarily sulfur oxides (SO₂), from flue gases. These pollutants are mainly produced during the combustion of sulfur-containing fossil fuels, especially coal. SO₂ is a significant air pollutant contributing to acid rain and having harmful effects on both human health and the environment.

Our technologies enable efficient reduction of SO₂ emissions using dry, semi-dry, and wet methods, with the choice of technology depending on the source size, operating conditions, and required efficiency.

Desulfurization Technologies We Offer

- Dry Process – involves dosing an additive (most commonly calcium hydroxide, Ca(OH)₂) before or into the reactor, where it mixes with the flue gas and reacts. A secondary reaction takes place on the filter fabric. The advantages include low investment costs, while the disadvantages are lower efficiency of 75%, although the process can be intensified by water injection.

- Semi-Dry Process – injection of an aqueous suspension of Ca(OH)₂ into the desulfurization reactor (spray dryer absorber). The flue gases cool down and water evaporates adiabatically. Quicklime (CaO) or calcium hydroxide is used. This method offers higher efficiency and lower additive consumption compared to the dry process.

- Wet Process – the most widely used method for large combustion sources. SO₂ is removed using a water suspension of limestone (CaCO₃) or calcium hydroxide. Finely ground limestone or dolomitic limestone is typically used. This method provides high efficiency and low sorbent consumption but requires higher investment and maintenance costs.

Desulfurization method using recirculation with water injection

Sorbent recirculation mixers include inlets for connecting humidifying water, which is supplied to reactivate the unreacted sorbent contained in the post-reaction product. This process improves reaction conditions and reduces sorbent consumption.

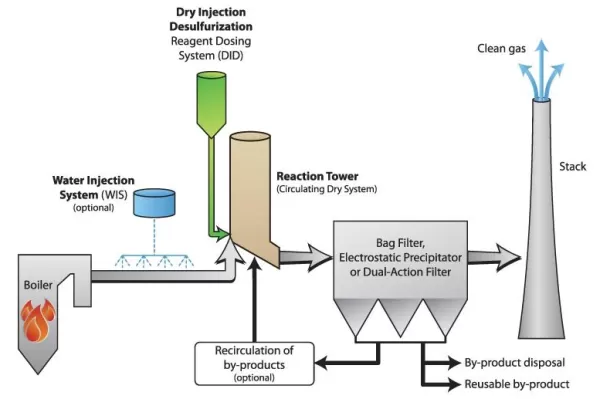

Diagram of the dry desulfurization process

Diagram of flue gas desulfurization and treatment.

Advantages of DEPURO Desulfurization Technology

- Multiple desulfurization methods – dry, semi-dry, and wet processes.

- High efficiency – up to 75% for dry process, with even higher efficiency for semi-dry and wet systems.

- Adapted to specific operations – technology selection based on flue gas temperature, SO₂ concentration, and available additives.

- Turnkey solutions – design, manufacturing, installation, and optimization.

Request a Flue Gas Treatment Technology

Do you need to reduce sulfur oxide emissions and meet emission limits? Contact us – we will design a desulfurization technology tailored to your operating conditions.