Reduction of gaseous pollutants – effective and reliable solutions for industrial operations.

Reduction of gaseous pollutants is an essential process for environmental protection and meeting regulatory requirements for industrial emissions. Combustion processes produce a wide range of harmful substances that must be effectively captured before being released into the atmosphere. These substances include hydrochloric acid (HCl), hydrofluoric acid (HF), volatile organic compounds (VOCs), and dioxins (PCDD/F).

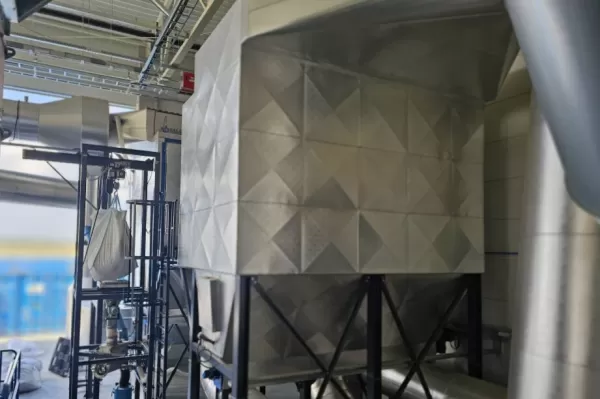

Our technologies primarily use the dry reduction process, which, due to its efficiency and operational reliability, is the most commonly applied solution. The efficiency of this method can exceed 90%, making it an ideal choice for a wide range of industrial applications.

Principle of the Dry Reduction Process

The dry flue gas cleaning process works by dosing an additive before or directly into the reactor. Here, the additive is thoroughly mixed with the flue gases, and a primary chemical reaction occurs. The subsequent secondary reaction takes place on the surface of the filtration fabric – this process is particularly intense in filters with reverse pulsed-flow cleaning regeneration.

This method is effective in reducing concentrations of HCl, HF, VOCs, dioxins, and other gaseous pollutants. Its operational advantages include not only high efficiency but also lower investment costs compared to the semi-dry and wet process, making it an optimal choice for operations seeking an effective and cost-efficient solution.

Advantages of DEPURO Flue Gas Treatment Technology

- High efficiency – removes HCl, HF, VOCs, dioxins, and other gaseous pollutants.

- Low investment costs and flexibility in method selection – multiple technologies available.

- Versatile application – suitable for various industrial processes.

- Combination with fabric filters – ensures maximum efficiency.

- Turnkey solutions – design, manufacturing, installation, and regular maintenance.

Flue Gas Treatment Technology Request

Would you like to effectively reduce harmful gas emissions and meet emission limits? Contact us – we’ll design a flue gas cleaning technology tailored to your operational conditions.