Electrostatic precipitator

Electrostatic precipitators (ESP) are among the most effective technologies for capturing fine dust particles and aerosols from flue gases. Their principle is based on the action of a strong electric field, which charges the particles contained in the gas stream and subsequently attracts them to the collection electrodes. The captured dust is then mechanically removed into containers.

How do electrostatic precipitators work?

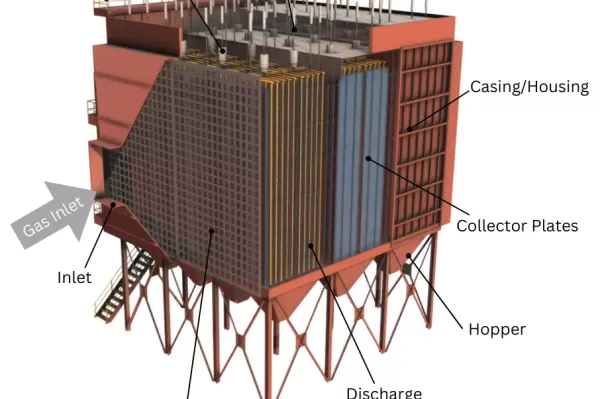

Inside the separator there are two types of electrodes. The discharge electrodes are connected to the negative pole of a high-voltage DC source and the collection electrodes are connected to the positive pole. The high-voltage electric current introduced to the discharge electrodes creates a strong electrostatic field between the discharge and collection electrodes. Due to the shape of the discharge electrodes and their high voltage, a so-called corona is formed on the surface of the electrode - a blue-violet discharge that produces negative ions. These ions charge the dust particles with a negative charge and the electric field subsequently attracts them to the positively charged collection electrodes. The particles are captured on their surface and are then mechanically shaken off or swept into a container.

Electrostatic precipitators advantages

- High efficiency, especially when capturing very fine particles.

- Low pressure drop (up to approx. 200 Pa).

- Capable of working at high volume flows and high flue gas temperatures.

Limitations and disadvantages

- Lower resistance to abrasive particles.

- Higher acquisition costs and the need for more space for installation.

- More demanding operation and maintenance.

- Limited use in dust with extremely high or very low electrical resistance.

Do you need a highly efficient separator for fine dust or aerosol?

We will be happy to design an electrostatic precipitator (ESP) solution that meets the exact requirements of your operation.